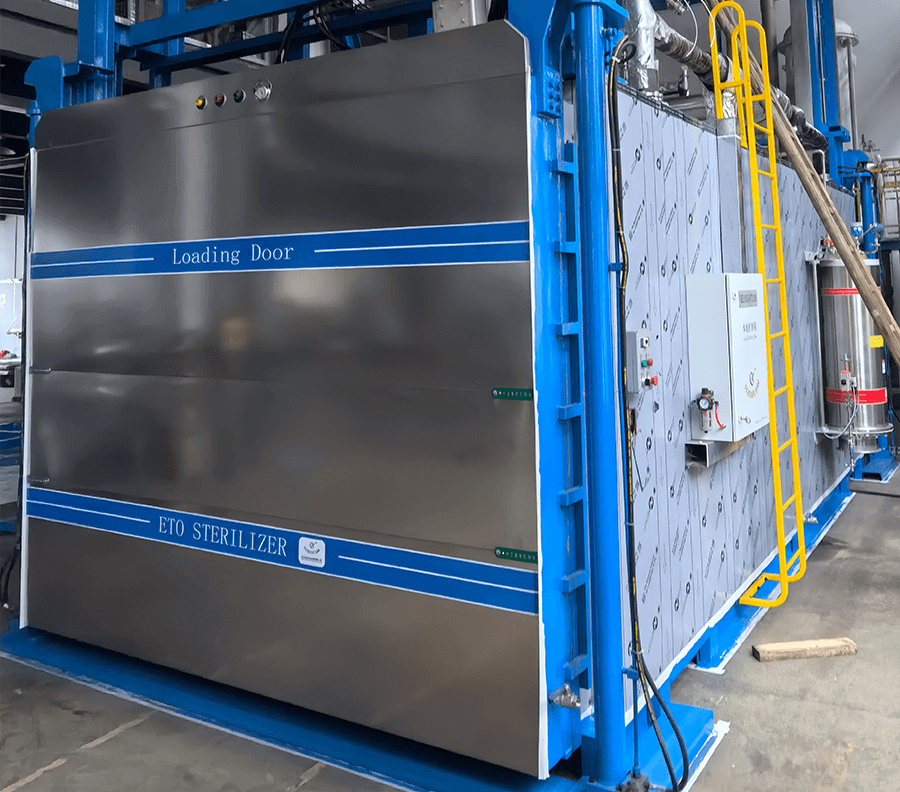

High-quality ethylene oxide sterilizer equipment with advanced technology, reliable performance and competitive price.

Capacity: 1 m³ ~ 130 m³, For 1~ 32 palltes

Temperature: 30℃~55℃, limit < 58 ℃

EO gas: 100%, 70%, 30%, 20%, 10%, or other.

Process: Each Sterilization Cycle Takes 7-10 Hours

Warranty: Cabinet Guaranteed For 5 Years. 30 Years Service Life.

Advanced sterilization solutions designed to meet the highest industry standards

2026 upgraded version of ETO sterilizer. Sterility Assurance Level (SAL)

| Capacity | 1m³ - 120m³, for 1 - 32 pallets |

| Temperature Range | 30℃~55℃, limit < 58 ℃ |

| Features | low temperature, efficiently penetrate |

| Cycle Time | 7-10 hours (depending on load) |

| Power Supply | 380V 50Hz/60Hz, or transformer |

| Normal pressure range: | -80kPa ~ +80kPa |

| Specific pressure range: | -99kPa ~ +99kPa |

| Optional door types: | Sliding, Revolving, Lifting |

| System control mode | Full- Automatic, Soft manual & by switching |

Remove EO gas residues from product and packaging after sterilization.

The aeration process can be carried out in the sterilizer or this separate aeration room.

| Function: | Remove EO gas residues from products |

| Capacity: | for 1 - 32 pallets |

| Temperature Range: | 37°C - 60°C |

| Cycle Time: | 12-24 hours (depending on load) |

| Power Supply: | 380V 50Hz/60Hz (Customizable) |

| Power Consumption: | varies by model |

| Dimensions (W×D×H): | 6000×3300×2500 mm (Customizable) |

| Weight: | 5 - 45Tons (varies by model) |

| Control System: | Advanced PLC |

| Emission standard: | 80mg/Nm3(44.4ppm), 40mg/Nm3(22.2ppm), 5mg/Nm3(3ppm) |

| Input: | Electricity & Soft water |

| Output: | @40%glycol |

| Materials available: | PPH, or stainless steel |

| Number of towers: | three-stage, five-stage, six-stage |

| Dimensions(W*D*H): | 12000*3500*6000mm (varies by model) |

| Installation location: | Outdoors or Indoors(pay attention to the height) |

| Routine operations: | Replace the waste liquid every 1-3 months |

| Note: | Sunshade for outdoor, Height for indoor |

Heat and humidify the product to prepare for sterilization.

This process can be carried out in the sterilizer or separate precondition room.

| Capacity | 1-32 pallets, compatible with sterilizer |

| Temperature Range | 37°C - 60°C |

| Cycle Time | 6-12 hours (depending on load) |

| Power Supply | 380V 50Hz/60Hz (Customizable) |

| Power Consumption | 20-50 kW(varies by model) |

| Dimensions(W×D×H) | 5000×3300×2500 mm (varies by model) |

| Weight | 2500-5000 kg |

| Control System | Industrial PLC + PC Monitoring |

Our EO sterilizers are engineered with cutting-edge technology to ensure optimal performance and safety.

Multiple safety protection systems to prevent accidents and ensure operator safety.

Fast sterilization cycle with uniform EO gas distribution for complete sterilization.

Intelligent touch screen control system with automatic operation and data recording.

EO gas recovery system to minimize environmental impact and reduce operating costs.

Hangzhou Bocon Mechanical And Electrical Co.,Ltd

With over 20 years of experience in ethylene oxide sterilizer manufacturing, we are a leading supplier of EO sterilizers to medical consumables and pharmaceutical companies worldwide.

Our factory covers an area of 20,000 square meters with advanced production lines and strict quality control systems. We export our products to more than 50 countries and regions, earning a reputation for reliability and professionalism.

Production line spanning 20,000 square meters

Our control system is highly praised by customers for its comprehensive functionality, excellent safety, and user-friendly operation.

The weld seam is smooth and aesthetically pleasing, with no defects, guarantee strong weld adhesion and corrosion resistance.

Advanced design, safe operation, and performance, it is safer and more cost-effective than combustion abator. Emission standard: 1mg/Nm3.

Trusted by professionals and industry leaders worldwide.

"The EO sterilizer has significantly improved our sterilization process efficiency. The equipment is reliable and easy to operate, and the after-sales service is excellent."

Medical Director, Turkiye

"We have been using their sterilizers for 10 years with no major issues. The quality is top-notch and the technical support team is always responsive to our needs."

Director of Engineering, Indonesia

"As a EO sterilization service plant in South Korea, we need reliable sterilization equipment. Their EO sterilizers meet all our quality standards and regulatory requirements."

Quality Manager, South Korea

Our team of experts is ready to assist you with your sterilization equipment needs.

Caitong Zhongxin, Xiasha District, Hangzhou city, Zhejiang Province

+86 18258800889

Jacky@hnbocon.com